When you think of industrial quality control, you probably imagine sampling, manual checks, or even destructive testing. But what if manufacturers could inspect every single product—without touching or damaging a thing?

That’s exactly the paradigm shift TiHive is enabling. With its real-time, see-through imaging powered by Terahertz and AI, the Grenoble-based startup is bringing radical transparency to production lines—from diapers to airplane parts.

Now, with an €8 million funding round co-led by Wind, Karista, and the European Innovation Council Fund (EIC Fund), TiHive is scaling its proven solution to new sectors: textiles, agriculture, recycling, and even aerospace.

A leap in quality control with measurable impact

TiHive’s proprietary technology doesn’t just replace sample-based inspection—it scans 100% of products on a line, in real-time, using ultra-high-frequency waves and AI analytics. The result is higher quality, lower waste, and a dramatically smaller environmental footprint.

Here’s what that means in practice:

- Up to 300 tons of raw materials saved per production line per year

- Around 1,500 tons of CO₂ emissions avoided annually

- Billions of products made faster, better, and more reliably

All without halting or altering existing workflows.

Why we’re backing TiHive

At Wind, we look for deeptech with real-world applications and scalable environmental benefits. TiHive fits both, combining scientific excellence with industrial pragmatism:

- Proven on the factory floor: Already deployed on hygiene lines, their tech is field-tested and ready for expansion

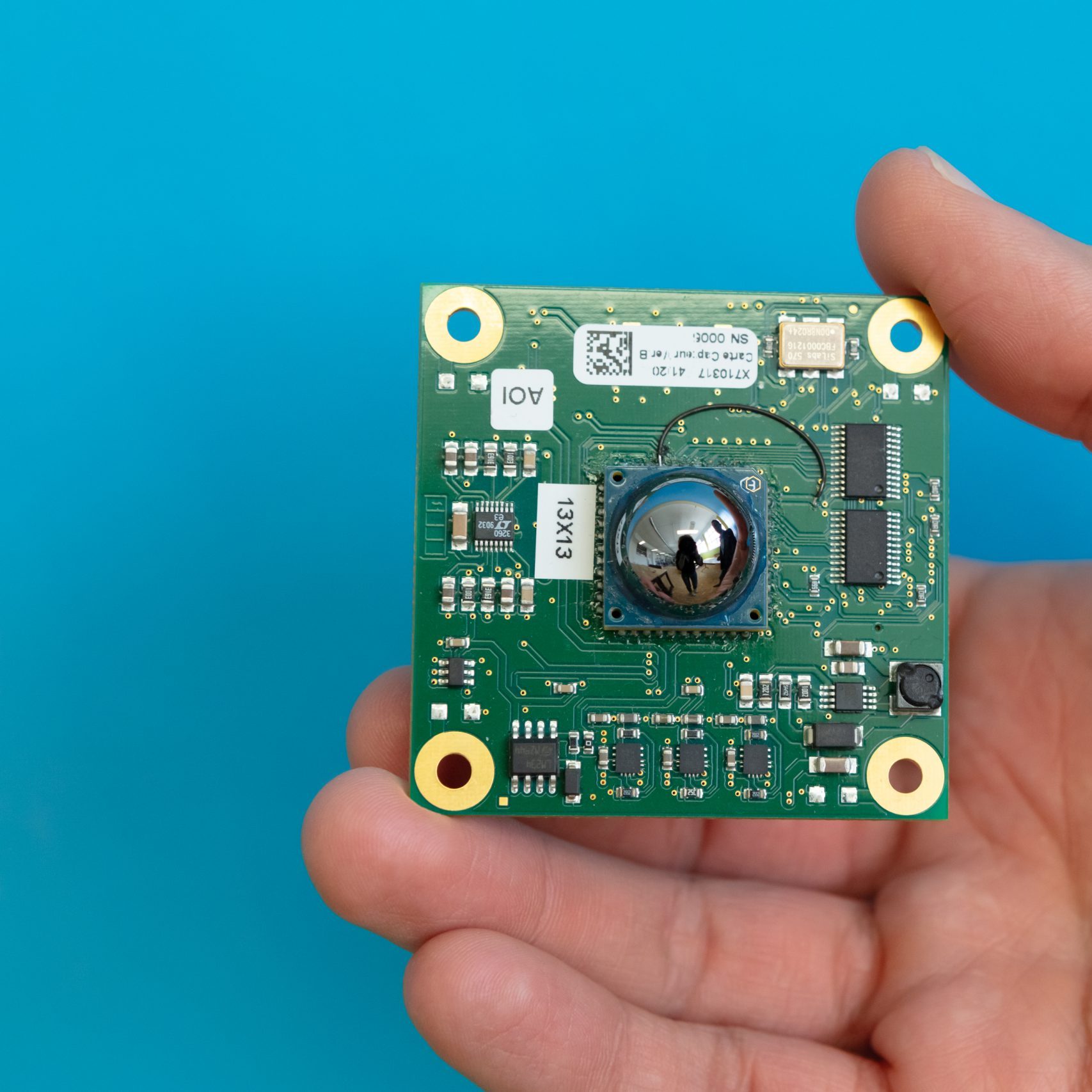

- Strong IP moat: A unique blend of custom terahertz chips and proprietary AI models

- Scalable to multiple verticals: Beyond hygiene, the roadmap spans recycling, textile manufacturing, smart agriculture, and space

- Pan-European momentum: This raise brings together leading European funds aligned around industry innovation and sustainability

As noted by TiHive’s founder and CEO Hani Sherry in Les Échos (17 November 2025), the goal is clear: to industrialize the technology and diversify its applications across sectors where non-destructive, high-speed inspection is both critical and under-addressed.

Europe’s edge in industrial deeptech

This investment reflects a broader trend: Europe betting on industrial deeptech to lead in both competitiveness and sustainability. With climate goals tightening and supply chains under pressure, tools like TiHive’s aren’t a luxury—they’re a necessity.

Backed by a powerful coalition of investors and already delivering measurable ROI, TiHive is a clear example of how precision hardware + AI can unlock both economic and environmental value in manufacturing.